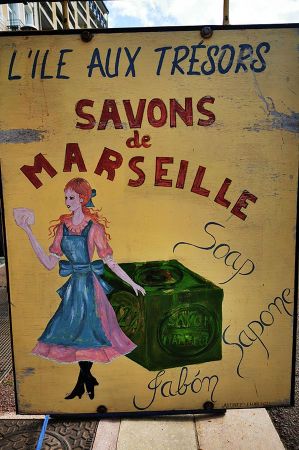

Savon de Marseille – the soap makers of Marseille

- Written by Portal Editor

In France, more precisely in Marseille, there is a so-called purity law that does not apply to beer like in Germany, but also to a very important product: soap made from olive oil.

The producers were so-called soap makers or soap boilers, who were first mentioned in the Marseille region in 1370. This type of soap production is much older and comes from Syria, more precisely from the region around Aleppo, but more on that later. The formula for producing this soap was clearly regulated in the 17th century under King Louis XIV, which still applies today. In 1688, Jean-Baptiste Colbert issued an edict restricting the use of the name “Savon de Marseille” to soaps made with olive oil in the Marseille region.

Colbert – pre-classical economist on improving French products

Colbert, Marquis de Seignelay, was a French statesman and the founder of mercantilism (Colbertism). It can be counted as part of the preclassical economy. He was a successful finance minister under the “Sun King” Louis XIV. He reorganized the state budget in order to finance the very high expenses, especially for the king himself, the court, the military and his military campaigns. Colbert created the basis of French economic and colonial policy. He saw the most important source of national wealth in an active foreign trade balance. By promoting and establishing manufactories, he tried to save the country from expensive imports. He brought foreign skilled workers into the country in order to be able to produce the best products from other countries in France. He also ensured that export duties were reduced and the country roads were expanded into permanent highways. He tried to increase the quality of the goods produced in France with detailed catalogs with production regulations.

Colbert, Marquis de Seignelay, was a French statesman and the founder of mercantilism (Colbertism). It can be counted as part of the preclassical economy. He was a successful finance minister under the “Sun King” Louis XIV. He reorganized the state budget in order to finance the very high expenses, especially for the king himself, the court, the military and his military campaigns. Colbert created the basis of French economic and colonial policy. He saw the most important source of national wealth in an active foreign trade balance. By promoting and establishing manufactories, he tried to save the country from expensive imports. He brought foreign skilled workers into the country in order to be able to produce the best products from other countries in France. He also ensured that export duties were reduced and the country roads were expanded into permanent highways. He tried to increase the quality of the goods produced in France with detailed catalogs with production regulations.

On October 5, 1688, an edict from Louis XIV, signed by Jean-Baptiste Colbert Seignelay, son of Colbert, secretary to the royal family, regulated the production of soap. Article III of the edict states that the soap must be cooked in large cauldrons and that no animal fats and oils may be used. The oil content must be at least 72%. The soap factories had to stop working in the summer because the heat affected the quality of the soap. Compliance with this regulation ensured the quality of the soap and made the reputation of the Marseille soap factories.

Origin of olive soap

As already mentioned, Aleppo soap is the oldest soap in the world and has been produced in a traditional, lengthy process since ancient times. In Arabia it is valued equally by women and men. Aleppo soap from Syria is 100% plant-based and free of any additives. The first-century Roman encyclopedist Pliny reports in his book Naturalis Historia that the Gauls used a tallow and ash-based product to dye their hair red. However, this particular soap worked more as a gel and hair bleach.

As already mentioned, Aleppo soap is the oldest soap in the world and has been produced in a traditional, lengthy process since ancient times. In Arabia it is valued equally by women and men. Aleppo soap from Syria is 100% plant-based and free of any additives. The first-century Roman encyclopedist Pliny reports in his book Naturalis Historia that the Gauls used a tallow and ash-based product to dye their hair red. However, this particular soap worked more as a gel and hair bleach.

As has been the case for hundreds of years, this Aleppo soap is still made with love by hand in well-known factories, cut and stamped with the stamp that makes each piece unique. Due to the 100% natural composition of the soap, it is completely degradable. It suits all skin types, even children. Olive oil cleanses and nourishes the skin without irritating or drying it out and supports the skin's self-regulating function. Due to its pH value (8 to 9) it is suitable for alkaline body care.

The comparatively mild, aromatic-spicy smelling, fine-pored and slightly foaming Aleppo soap is a simple curd soap. It has been made for many centuries (possibly since the 8th century AD) by soap makers in and around Aleppo during the “cold” months of November to March. Today the majority is exported to Europe and East Asia as natural cosmetics, although business has declined significantly as a result of the civil war in Syria.

The comparatively mild, aromatic-spicy smelling, fine-pored and slightly foaming Aleppo soap is a simple curd soap. It has been made for many centuries (possibly since the 8th century AD) by soap makers in and around Aleppo during the “cold” months of November to March. Today the majority is exported to Europe and East Asia as natural cosmetics, although business has declined significantly as a result of the civil war in Syria.

In traditional artisanal production, olive oil is heated to boiling point in bottom cauldrons over an open fire for up to three days, stirring frequently, at around 200°C. For saponification, water and soda ash are added in portions. The olive oil is broken down into the sodium salts of the fatty acids, the actual detergent substances, and glycerin.

After this saponification process, shortly before the salting is complete, laurel oil is added, the proportion of which usually varies between two and 40 percent, rarely up to 60 percent, of the oil quantity. This increases the strength of the soap when it dries later, the fine-pored foaming when it comes into contact with and rubbed with water, as well as the moisturizing and antibiotic effect when used on skin and hair.

Depending on the recipe, medicinal and fragrant herbs as well as scented oils (e.g. rose oil) are also added during production. After boiling, the soda lye is drained.

Depending on the recipe, medicinal and fragrant herbs as well as scented oils (e.g. rose oil) are also added during production. After boiling, the soda lye is drained.

The soap is then “washed” with fresh water until it is free of lye. After this water has also been drained, the soap is left overnight to cool and dehydrate. The green soap paste is then removed from the kettle and poured out onto a smooth floor surface lined with foil and smoothed out. The soap hardens and dries out there for at least 24 and up to 40 hours.

The hardened mass is then cut into rectangular soap bars. After cutting, the pieces are sealed with a traditional embossing stamp. Stacked with gaps on wooden pallets, they are stored in an airy, dry place for six to nine months, which, in addition to further drying and curing, causes the soap bars to oxidize on the outside and thus take on a patina with a light, honey to sand-colored tone, while their core has the original greenish color Mainly retains colour.

Effects and possible uses

The ancient Greeks and Romans used laurel soap, which has high levels of linoleic acid and is rich in vitamins A and E as well as minerals such as potassium, magnesium and calcium, for body cleansing, skin care and wound healing.

The ancient Greeks and Romans used laurel soap, which has high levels of linoleic acid and is rich in vitamins A and E as well as minerals such as potassium, magnesium and calcium, for body cleansing, skin care and wound healing.

Thanks to the laurel oil in particular, the soap has an astringent, antibiotic and antifungal effect on the skin, as well as being a cleanser and also stimulating and moisturizing. Medically it was used in particular against scabies, lice infestations, psoriasis, nail bed inflammation, acne and eczema (neurodermatitis).

It is also said to provide relief from common insect bites and abrasions as well as from bruises, sprains and rheumatic complaints. It is also used to wash hair (including beard wash) and against dandruff.

The emergence of the Marseille soap industry

The method of production, based on olive and laurel oil, spread throughout the Mediterranean after the Crusades through Italy and Spain to Marseille.

The method of production, based on olive and laurel oil, spread throughout the Mediterranean after the Crusades through Italy and Spain to Marseille.

The 12th-century Marseille soap factories initially used only olive oil produced in Provence as raw material. The soda, a term that at that time refers to a more or less pure sodium carbonate, came from the ashes of plants in saline environments, especially Salicornia. It is sufficient to collect the combustion residues of the plant substances with a high salt content and extract them by dissolving them. To do this, the wet ash was placed in a cloth bag and squeezed out using long sticks. The liquid containing the soda and other sodium salts was collected in a vat and left in the sun until the moisture had evaporated. The same procedure was used to obtain potassium salts from wood ash. In 1371, Crescas Davin is mentioned as the first soap maker from Marseille to use soda. In 1593, Georges Prunemoyr went beyond the artisanal scale of soap production and founded the first factory in Marseille.

At the beginning of the 17th century, the production of soap factories in Marseille barely met the needs of the city and its territory. Soap from Genoa and Alicante even arrived at the port of Marseille.

At the beginning of the 17th century, the production of soap factories in Marseille barely met the needs of the city and its territory. Soap from Genoa and Alicante even arrived at the port of Marseille.

In 1660, there were seven factories in the city, whose annual output was nearly 20,000 tons. Under Louis XIV, the quality of the soap was so high that “Savon de Marseille” became a household name. It was a green soap sold primarily in 5kg bars or 20kg wheels.

The Marseille region had around 90 soap factories in the 19th century. After 1950, the rise of synthetic cleaning products began their decline. China and Turkey are today the largest producers of Savon de Marseille. The name “Savon de Marseille” is not a registered designation of origin, but only corresponds to a codified manufacturing process that guarantees a minimum fatty acid content. This process can use fats other than olive oil, including tallow of animal origin.

Please read as well:

Hottest stars of pop music in Prague - British singer Raye

A destination: Lechtal when the lady's slipper is blooming

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

-

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

Marseille - wellknown for its soap production

https://www.alaturka.info/en/france/marseilles/6598-savon-de-marseille-the-soap-makers-of-marseille#sigProId5414db9455